When it comes to pharmaceutical and healthcare products, many of which are subject to stringent regulatory law, manufacturers and suppliers must be meticulous when it comes to packaging. After all, products must reach the consumer in perfect condition to be effective and, more importantly, be safe for use.

Packaging specialists have a lot to consider when it comes to the packaging of their products. Chemical and physical stability of the formulation, product integrity, safety, packaging processes and delivery methods all play a key part in determining shelf life of a product.

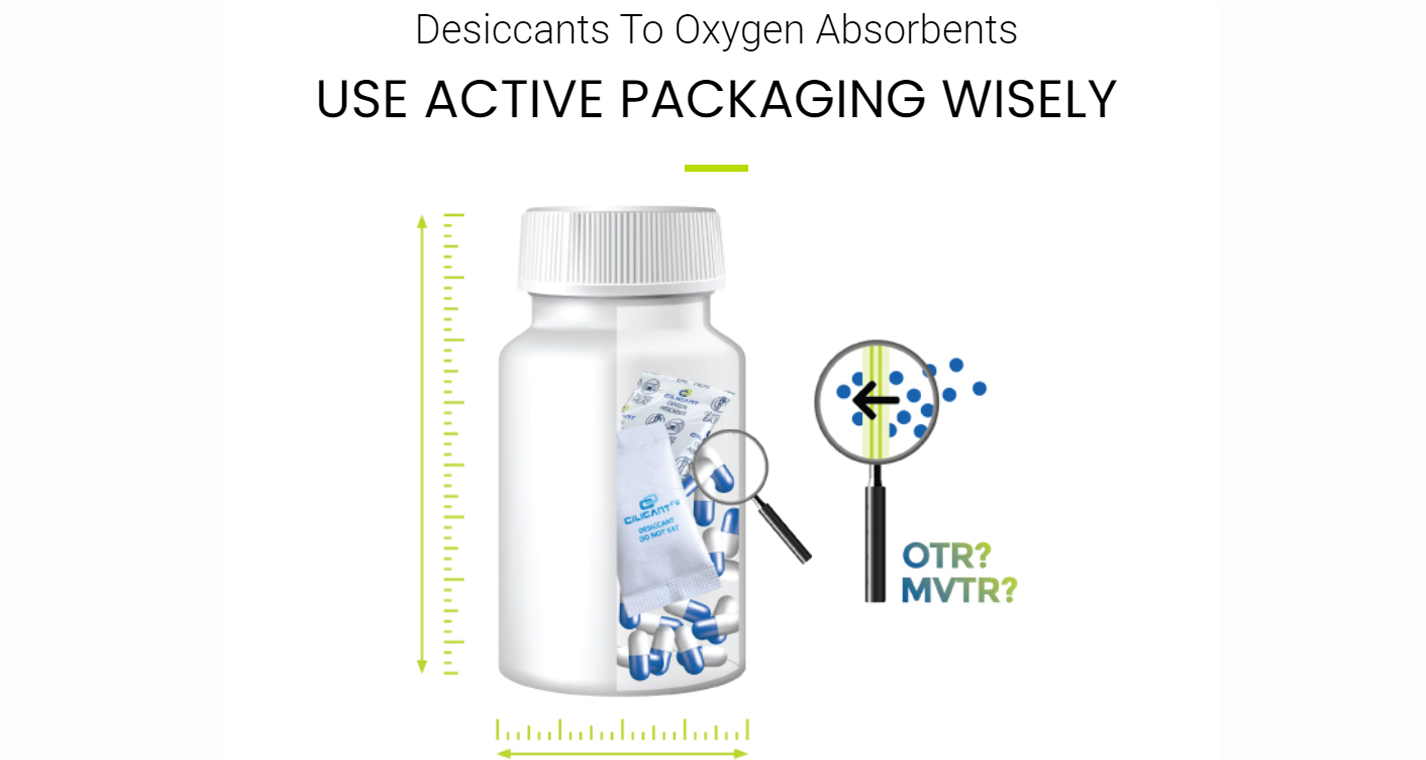

Which is where Active Packaging (AP) comes in. Medicines, health supplements, medical devices, surgical equipment and diagnostic kits all need specialised protection, where elements such as desiccants and oxygen absorbers are added to ensure that they are effective, wastage is reduced and they are completely safe for patient usage.

Active packaging – Protect your customer

Active packaging is a vital consideration when it comes to protecting pharmaceuticals and other medical supplies from oxygen and moisture. Typically, this involves including protective products in or on the packaging to reduce damage and degradation.

Ultimately, the quality of active sorbent technology will play a key role in how successful manufacturers are when it comes to shelf life and end-user safety. But not all desiccants and oxygen absorbers are the same. Generic products won’t deliver optimal benefit to end-users or suppliers.

Clearly, there is a huge range of pharmaceutical and medical products out there – all with varying needs when it comes to active packaging needs, so we’ve designed our products to meet a wide range of uses. Significantly, they are also compatible with each stage of the packaging and distribution process. For example, all our products are compatible with high speed packaging systems.

Built for purpose and designed for effectiveness

Our active sorbents come in five different product types, which makes them suitable for a wide range of pharmaceutical and medical supplies. These include silica gel, molecular sieve (fast-working for products that need instant protection from moisture), activated carbon (ideal for odour control) and a custom blend for both odour control and tackling moisture-induced degradation, as well as oxygen absorber for protection against oxygen induced degradation.

We pay attention to the small details that can make a big difference to patient safety. From the non-tear, non-lint packaging film to 21 CFR compliant printing ink suitable for direct contact with medicines.

Meeting and exceeding all standards

Of course, it’s important to choose a reputable active packaging supplier that meets regulatory standards. Cilicant products are manufactured in a classified cleanroom and ISO 15378 cGMP facility.

Throughout the design process for our products we are focussed on end-user protection. All our products are non-toxic, spill proof and safe for direct contact – all factors that can help support your marketing efforts.

We believe it has been this commitment to quality and exceptional high standards that has made Cilicant the fastest growing active packaging company in India.

For more information on the best desiccants and oxygen absorbers for your product, get in touch with our expert.